Transparency

Our goal is to craft our handbags following a transparent and responsible supply chain.

The value behind our creations goes beyond the pure aesthetic. It bears full consideration of the people involved in the productive process, of the surrounding environment and of the raw materials’ quality.

From the selection of the raw materials to the final quality control of the handbag, we trace all the actions undertaken along the supply chain. The analysis of the results allows us to improve and foresee the potential benefits on the production process.

Passion and experience are at the heart of our work. We aim to set the breeding ground on which these values can prosper.

Our know-how and how we communicate it

Production

Our products are handmade. Their timeless designs do not follow seasonal trends or the fashion calendar. Our handbags are meant to be worn as long as possible. To achieve this goal, we foster the delivery of high quality from our crafting process. Among our activities, we invest a lot of resources in the selection of the right materials and the control of their quality and origin.

The high-end leather craft is a complex process because it is entirely handmade and requires the cooperation of many people. Details are defined by the artisans’ expertise, not by an industrial machine. As an example, let’s consider a handbag from the Haute Couture line, decorated with embroidered pleats. Leo Camerini design studio coordinates three different highly skilled ateliers spread between Italy (handbag atelier) and France (embroidery and pleating ateliers). Other suppliers may be engaged, if it is necessary to have an in-depth study on specific materials. Finally, the entire crafting process counts around 15 to 20 people.

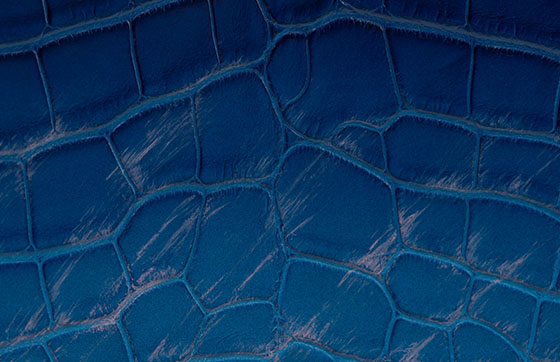

We have also established an internal methodology that helps us to avoid wastes of materials, especially concerning crocodile leathers. Through our cutting system, we know how much leather we consume for each bag model. Therefore, we are able to optimize the consumption because we can select the right leathers for each model and size.

All these efforts demand a lot of time and stretch our production time-table. We are happy and proud to follow such practice because we know we will receive long-term benefits.

Relationship with our suppliers

We put a lot of efforts building stable partnerships with our suppliers, based on mutual trust and respect of each other’s work ethics. We have spent a lot of time evaluating and strengthening our relationships with few companies. By knowing the people behind the materials, we can appreciate their quality.

We are supported by our suppliers not only during the production process, but also in the collection of all the necessary reliable information regarding to the raw materials and the related sourcing activities. Thanks to their help we can guarantee a high level of traceability all over our supply chain.

Relationship with our customers

As part of our communication strategy, we try to be at the forefront of the conversation with our customers. We constantly work on developing our online and offline channels in order to reduce the distance between us and our customers. Not only we nurture the direct dialogue, but we also encourage it.

We share updates during the crafting of the handbags. Customers do not feel abandoned thanks to our prompt customer service. We are fully open to provide our customers with any information regarding to raw materials, leather tanning and the other production practices we follow.

Responsible sourcing of natural materials

We use natural materials for the crafting of our products. Such materials come from animals already designated to other industries, such as food and agriculture.

All the purchased crocodile and alligator leathers and the peacock feathers come with a certificate of the Convention of International Trade in Endangered Species of Wild Fauna and Flora (CITES), also known as the Washington Convention. Consequently, we provide customers either with a company’s declaration (for products sold within the European Union) or with a CITES Re-export certificate (for products sold outside the European Union).

This document carries all the information regarding to the traceability of the leather: common name of the animal, scientific name of the animal, country of origin, CITES Appendix and source.

All our leathers and feathers are dyed with hues in adherence of the REACH European regulation.

We source the following natural materials:

- Crocodile and alligator leathers;

- Lambskin;

- Calfskin;

- Natural feathers: duck, goose, guinea fowl, peacock, pheasant, wild heritage turkey.

1. Crocodile and alligator leathers

Origin: Australia, Indonesia (Crocodile Porosus); U.S.A. (Alligator)

We work with one of the leading tanneries in the World. This supplier actively collaborates with government and non-government organisations on matters concerning the crocodile leather trade industry in favour of the protection and conservation of endangered crocodilians species.

2. Lambskin

Origin: European Union

The tannery that supplies lambskin to us has a 150 years old tradition. It is among the early players which has adopted a global environment strategy. It conducts strict controls all over the transformation process of the leathers.

Recognized in France with the label “Entreprise du Patrimoine Vivant”, this supplier promotes the consumption of raw materials for the benefits of local communities.

3. Calfskin

Origin: European Union

The tannery has implemented a sustainability policy that minimize the impact on the environment. The company works in order to have direct knowledge on the raw material origins and traces all the steps of the production chain. Moreover, the company has established tight collaborations with local consumer agencies and educational organizations to foster the correct management of the leather industry value chain.

4. Natural feathers

Origin: P.R.C., U.S.A.

Leo Camerini uses feathers to ornate some of its models of the Haute Couture line. All the feathers come from species raised in captivity and designated to the food industry. Peacock feathers are protected by the Washington Convention. We release a CITES certificate for all the handbags decorated with such feathers. We receive both natural-coloured feathers and feathers directly tainted by our suppliers. All feathers are sterilized before they are embroidered on the bags.

Other materials

1. Embroideries

Embroideries are complex systems of different components, from natural and artificial origins.

Embroideries are stitched on lambskin or textile fabrics (e.g. satin). The main components of the embroideries are:

- Various type of sequins (e.g. round, square and milled paillette, cuvette);

- Imitation pearls;

- Metallic studs;

- Textile artworks (e.g. organdie ribbons, multi-layer fibres).

The first three genders include products composed of polyester and other plastic derivatives. We use these materials because we value that to date there are not alternatives that can achieve the overall quality level we require for our products. The metallic items are mostly made of brass. Textile artworks are mostly based on cotton.

2. Metal accessories

Metal accessories are designed by Leo Camerini and are manufactured in Italy by a company specialized in components for fashion and leather products. We define the following items as “metal accessories”:

- Based studs (Leo30, Shoulder Bag);

- Chain (Gemelle, Shoulder Bag);

- Frame (Gemelle);

- Handle and Strap rings (Handbag 3.3, Leo30, Shoulder Bag);

- Lock (Handbag 3.3, Leo30, Shoulder Bag);

- Snap-hooks (Handbag 3.3, Leo30);

- Strap twin (Handbag 3.3, Leo30).

The metal accessories are made of brass and coated with 0.5 or 1-micron layer of precious metal (e.g. gold, palladium, ruthenium). The thicker the layer is the more resistant to external agents (e.g. humidity, solar light) and to time pass the coating will be. Not to mention, that the thickness of the plating also measures the level of preciousness. Our specification is abundantly above the industry standards.

After the coating phase the components undergo to the important anti-allergy treatment. In accordance to our quality standards, this last step is very important for the safeguard of the consumers.